Look and Feel

Model Suitability (out of 10):

Attributes (out of 10):

Copy paper is cheap, it's available almost everywhere, and yet few consider it a "real" origami paper. We decided to review it not because of any special origami related properties, but simply because it's there! As such, it can be used as a benchmark with which to compare the other reviews and values of properties.

On a personal note: I got Harbin's book "Origami 1" in 1976 and back then no other paper types were available in my home town, or indeed in all of Israel! I had never seen kami or any other origami paper. The only paper I had was printer paper, so my whole origami collection was white as snow. For me it was the only origami paper for years.

Paper production

The process of making this paper is fundamental in understanding some of its properties. The pulp is ground, diluted with water, spread over a felt belt, pressed to drain the water, and then spread on a net to be dried and rolled. A more detailed description of this process is also published here, see The Making of Printer Paper.

Copy paper is made for office and home use. The main goal is to enable printing at high quality. Faxes, homework, and monthly reports all require the ink to seep into the paper just far enough. The ink should not blot, but we all want the printed letters to have sharp borders. Colors should stay true when printing pictures. In the USA alone 85 million tons of paper are used every year for this purpose. But is it worth folding?

Properties

- Thickness: The most common weight is 80gsm. However, you can find a range of weights, starting from 50gsm and going beyond 120gsm. For our test we used the most common printer paper at 80gsm. Just like Tant, it's a medium thickness, not thin, not heavy. The actual thickness of the paper is 105 microns.

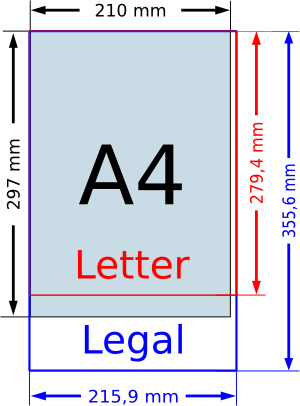

A comparison of A4, letter, and legal paper sizes, also see the original image, which includes A0 down to A8

A comparison of A4, letter, and legal paper sizes, also see the original image, which includes A0 down to A8 - Sizes: A whole array of sizes is available, but very few (if any) squares. In the US and Canada the most common sizes available are legal, quarto, and letter. These sizes are based on an old British system. There is also an ANSI standard used in the US, which is based on the ISO standard, but which uses letter as its foundations. However, the most common sizes of printer paper are defined by ISO 216, with three main categories: A, B, and C. All have the same proportion of 1 by square root of 2. This ratio has the unique property that when cut or folded in half lengthwise, the halves also have the same aspect ratio. The most common sizes are A4 (210×297mm), A3 and A5. See the Wikipedia article on ISO 216 for more details. There are also many "non-standard" sizes available, including rolls of plotter paper 36 inches wide, or 70mm memo-block squares.

- Colors: The most common shades are white and cream. Pastel shades and high luminenance colors are also widely available. The paper always has the same color on both sides.

- Paper Coloring or Colorability: This is a good paper for coloring. The paper is made for printing, which is a way of coloring it. However, washing the whole page with colour may result in stains on the other side if applied a bit too generously. Since coloring involves wetting the paper, it behaves accordingly. It doesn't expand uniformly, ripples are formed and when it dries, the paper is far from being flat. There are methods for avoiding this, but that is an entirely different topic.

- Texture: Smooth and bright white. During the production of this paper chalk (or a similar material) is added to make the surface as flat as possible. The fibres are very short. When looking at the paper while holding it against a light source you can notice the unevenness of the diluted spreading of fibres, just like a stained glass covered with dust. The transparency is quite high, since the paper is white and of medium thickness.

- Aging and Wear and Tear: it's all about the lignin, a natural ingredient from the wood. If the paper is acid free, it means all of the lignin was washed out. If some is still there, oxygenating will cause it to get brownish. You may have seen this effect on older newspapers. With high quality paper the discoloring will only become visible after a few years. For normal quality printer paper, aging is not a strong point. After a year or two, the paper tends to lose its dexterity and become stiff and its brightness is dimmed.

- Memory: Good. You make a crease and it is immediately visible to eye and touch. Fold a valley fold and let the paper free, it will bounce back a bit, but will remember the new position. 7 out of 10.

- Forgiveness: Reversing a fold is very easy, almost effortless. Folding a mountain fold weakens the paper so much, it hardly resists valley-folding it. The score here is 9 out of 10.

- Tensile strength: Tensile strength is the maximum stress the paper can undergo while being stretched or pulled. This is not a strong paper. It took 8 creases to get ripples and 31 to tear it. It's actually the weakest paper we have tested so far. While strengthening a crease with your finger nails, you can almost feel the paper perish. Having had free access to a Quality Assurance laboratory in a paper mill, I managed to measure the true strength of the paper - it takes 7 Kg to tear this paper along the fibers, and 2.9kg to tear it perpendicular to the fibers. In the process, the paper expands by 2%, and 4% respectively. A piece of 20cm was stretched by 3.67mm before being torn. In comparison, Elephant Hide tore at 15kg along the fibers, and at 7kg perpendicular to the fibers. In the process it expanded by 3% and 8% respectively. We rate the strength of printer paper at 4 out of 10.

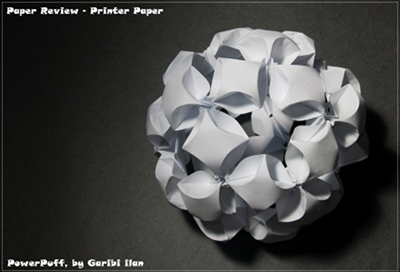

- Bending resistance: Bending resistance relates to the amount of force required to bend the paper. Although the PowerPuff unit curved surfaces seems smooth and strong, this paper is weak, and has little bending resistance. There is no real resistance to the touch and it is squashed too easily. 4 out of 10.

- Photogenic: Taking a picture of a model made from white paper is a simple task. It's more about light and shadow, and you can always go to Black & White filter on Photoshop, which makes a wonderful effect. Make sure to do some light measuring on the model before photographing.

- Where to buy: Everywhere! If you are looking for A4 or Letter, any office supply store will provide you with 500 sheet packs very cheaply.

Test results

Traditional use

Crane, 15×15cm

The folding experience is good. The paper responds well; you get sharp points if you plan your steps in advance, making a bit of room while narrowing the tail and neck. Reversing the creases to make the petal fold for the wings requires little pressure, and the wings stand up.

Action model

Barking Dog, by Gadi Vishne, 15×15cm

This paper works well for simple action models, but it is too soft for complex ones. The dog works nicely, although after few pushes it won't go back all the way anymore.

Traditional Flapping Bird, 15×15cm

The Flapping Bird, which we test for the pull value of the paper, shows the weakness of the paper. It tears quite quickly, especially if given to a small child.

Traditional Jumping Frog, 15×15cm

The Frog jumps nicely and performs similar to the frog folded from Tant. For best results, do make sure the legs are folded against the grain (fiber direction).

Modular/Unit Origami

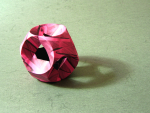

PowerPuff modular by Ilan Garibi. 30 units, 15×15cm

Folding this model was easy. No real effort is needed, except for keeping the face of the unit clean from unwanted creases. The paper is simply too weak. During the folding the center of the paper got a crease line just by being pressed against the paper edge underneath it. The friction is good, and the connections hold firmly. The weight is relatively low, so the model easily keeps its shape under its own weight.

Icarus Cube by Dave Mitchell. 6 units, 10×10cm

The paper remembers its creases quite well, but it is too soft. Its weak bending resistance makes it unsuitable for big units. On the bright side, the friction is high enough to hold this model together.

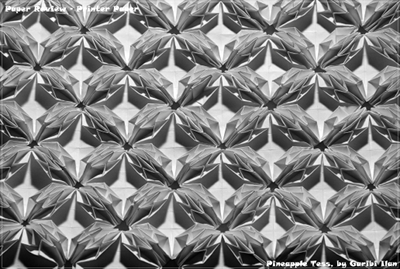

Tessellation

Pineapple tessellation by Ilan Garibi, 30×30cm

Folding a grid is an easy task here, very little pressure is needed to crease and reverse the it. Collapsing is harder, since the paper is too soft and does not jump into place. This results in a lot of unnecessary crimps.

Mystery tessellation by Ilan Garibi, 30×30cm

When folding this tessellation I have to change several folds to create the somewhat twisted looking connection between the pyramids. This requires a lot of forgiveness and flexibility from the paper. The flexibility of printer paper is high, but due to the weakness of the paper the surface is distorted. So the result not nearly as clean as folded from Elephant Hide, for example. When back-lighting the model, you can see an effect, of course, but with white shades only it's a bit dull.

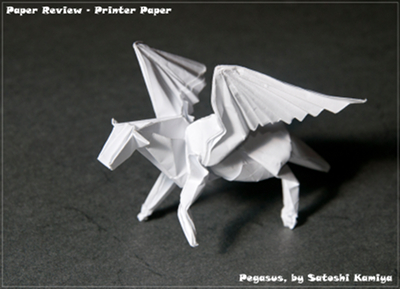

Complex

Pegasus by Satoshi Kamiya, 25×25cm

Don't use this paper for complex models. It tears easily and can't hold any shaping of the object. The paper surface fades when you mess with it. And when folding complex models, you have to mess with the paper.

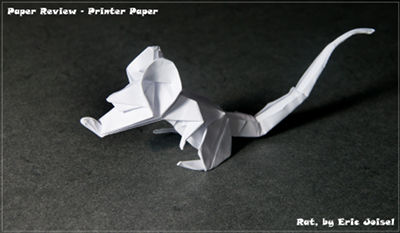

3D models

Rat by Eric Joisel, 25×25cm

Joisel's Rat covers most of the paper disadvantages. It was awful to fold, but still the result looks good.

Fox Terrier by Francisco Javier Caboblanco, 20×20cm

Wet folding is NOT recommended with this paper. Although using an almost dry sponge, the paper sucked all the water and became too soggy, unmanageable and easily tore. When dry, the surface rippled and the edge of the paper showed tiny fibres sticking out. As it has its own flexibility and memory when dry, wet folding printer paper is an unnecessary and unsuccessful experience.

Final verdict

We have a saying in Israel: "In the desert, even a thistle may be considered a lovely flower."

For traditional and simple models printer paper is good. It's the right weight and for undemanding models it delivers. This applies less for action models, which requires a strength and mobility that printer paper doesn't have. For tessellations it is not recommended; it can be done, but the final model won't have great appeal. The model will have a lot of unwanted creases and will age and fade relatively quickly. For 3D models it's barely OK; there's no need to wet fold to achieve desired shaping or volume to the final model. For complex models it is too weak and definitely not recommended. If you find a memo pack that is cut to an accurate square (which is rare), it works well for modulars, but otherwise, cutting A4 to squares is too much work.

This paper is always available and usually cheap and this may be its best property. It being either as strong as some papers, nor as weak as others, it's an average paper.

Flickr Statistics

Searching for copy paper images on Flickr, I found around 700 images. The majority of these were modulars. About a quarter were tessellations, about 50 were 3D animals (mostly simple ones), and only one picture showed a complex model (a lion by Kamiya). Strangely, 95% used colored copy paper, rather than the ubiquitous white!

Bottom line: Draft paper.

Please write your comments and feedback directly to us:

Ilan Garibi - garibiilan(at)gmail(dot)com

Gadi Vishne - gadi(at)vishne(dot)com

Comments

Submitted by Anonymous (not verified) on 6 June 2011 - 9:15pm Permalink

What do you mean by draft

What do you mean by draft paper?Is it like "use it for testing a model out before actually folding it"?

Submitted by Sara on 8 June 2011 - 8:14am Permalink

Draft paper: for test folds

I think Ilan means by "draft paper" paper that you'll use for test folds, yes.

-- Sara

Submitted by Anonymous (not verified) on 10 June 2011 - 12:49pm Permalink

yes, I did

Thanks, Sara, this is exactly what I meant.

Ilan

Submitted by Anonymous (not verified) on 7 June 2011 - 8:53am Permalink

Anything but plain photocopy paper

I am constantly delighted with what I can get copy paper to do - my aim this year is 365 folds, all with copy paper, doing quite well also - http://www.wonko.inf...

The material is almost exclusively copy paper - 80GSM plain white - taking photos of it is interesting, playing with light and shadow is too.

Submitted by Sara on 8 June 2011 - 8:21am Permalink

Nice project!

I think there's much you can fold with copy paper, and the plain white can be quite impressive. I find the simplicity of the paper puts the center point on the model, which can be a very intriguing thing.

Me personally, I do prefer choosing paper that I think suits the model. And that's almost never printer paper. But opinions differ a lot on paper choice in any case. :)

-- Sara

Submitted by Anonymous (not verified) on 10 June 2011 - 12:48pm Permalink

white paper is not only copy paper

Your project is admired and beautiful, not the least because of using white paper exclusively. the effect of all white is great, but I prefer white Tant, or even Onion Skin paper.

Ilan

Submitted by Anonymous (not verified) on 23 June 2011 - 3:58am Permalink

Name Confusion

Hi,I just folded the Icarus cube(reverse engineer) and I would like to ask if anybody knows why its called that.I'm just confused as it seems it has no relation to Icarus at all.

Submitted by Anonymous (not verified) on 14 July 2011 - 5:38am Permalink

Icarus

The cubes looks like it has wings, so instead of "Winged Cube", the creator probably wanted to be a little more creative. That's probbably the only explination.

Submitted by Anonymous (not verified) on 3 November 2011 - 3:48pm Permalink

Amazing! It's actually more

Amazing! It's actually more than I hoped to find. I needed this information not specifically for folding but for printing services that also involve folding at some point. Thanks for sharing the information, it's been very helpful!

Submitted by Anonymous (not verified) on 12 November 2011 - 2:39am Permalink

Another opinion

Firs of all I'll like to thank the site crators for there grat paper reviws.

However I feel like I have to defend the printing paper in this case.

Printing paper is far from beang exlent for origami however, it offen gives a good fight to a cami and even foil, exept of the obivious disadvanteges of coler and size limitations (those disadvantages can be partialy overcome since there are cheep A3 colerd printing papers).

The reson I think so is that one can actualy use wet folding. I using uncoman wet folding tequnic. Probly it often not as good as the coman ones however it alows to aplay it to papers that usualy no accesebale with wat folding. It also alow unexpirance folders like me to use it.

If u r interested I can postu some photos of relativly good results with printing paper (In this case you will have to explain me how to post photos). Also if the public will thik that those results are good enouf I can add some ditails about the methos.

yours,

Rami

P.S. plaese forgive my poor gramar and spelling there due to my dislecsia